Tele Vue APO Design and Build “Secrets”

Over the years, we’ve seen conversational topics in online amateur circles that repeatedly crop up concerning the definition of apochromatic refractor, triplet vs. doublet design, and how glass designation might define performance. We expect these questions to continue to appear as new amateurs discover the hobby. So bookmark this blog post because here you’ll find notes on Tele Vue’s philosophy and build practices concerning our telescope line of 100% APO refractors.

What is an APO Refractor?

Judging from some of the responses we’ve seen to this question, the debate is akin to interpreting biblical passages and constitutional amendments. There is valid reason for that. Most references describe an apochromatic objective as one whose design brings three widely spaced wavelengths of light to a common focus while correcting for spherical aberration (light focusing before or after the ideal focal point depending on where it enters the objective) for two wavelengths furthest apart.

The definition doesn’t mention the specific wavelengths of light to consider, the number of optical elements, or the type of optical “glass” required to pull off this feat. Importantly, it also neglects the affects of higher order spherical aberration, which if left uncorrected can make a design which would otherwise fit the apochromat definition “appear” not as well color corrected as one might anticipate. Neither does it mention any certification testing because there is no definite line to cross when it comes to applying the term “apochromatic.”

So, how does a consumer know their “APO” is an APO? To paraphrase Supreme Court Justice Potter Stewart’s famous comment about a certain movie genre, you’ll know it when you see it. Experience and expectation play a big role. Al Nagler’s 1998 “Statement on Apochromatic Performance” laid out a simple and practical test.

All our current scopes are APO refractors and they all offer a combination of versatility, performance, portability, and build quality unique in the industry. Tele Vue telescopes are engineered and built to be your life-long observing companions; and someday, your kids’ as well.

Quality Construction

Beyond top-tier optical performance, what makes our scopes so uniquely “Tele Vue” is the hand-built nature of each instrument. As we have done since we built our first air-spaced scope, objectives are individually spaced in increments of 0.1mm and manipulated in rotation and position within the cell in order to achieve the optical performance dictated by the design.

Optical Assembly & Collimation

The focuser is another critical part that can’t be overlooked: if it doesn’t move the drawtube smoothly or sags under weight, the image in the eyepiece/camera will not do justice to the expensive glass at the other end of the tube.

Hand-Fitted Telescope Focuser

The final area of concern is in maintaining the highest contrast level possible. Each lens element has a multi-coating designed for its specific glass type and all interior surfaces of the metal work are treated to various forms of stray light suppression.

For these reasons, each scope is assembled from beginning to end by one person. There are no assembly lines or quotas in our manufacturing process. Optical and mechanical components are inspected, fitted, assembled, aligned, and scrutinized so the end result is a telescope that is as good as we can possibly make.

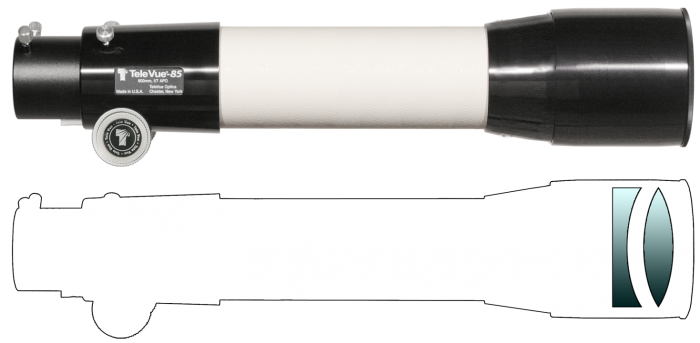

Tele Vue Small Doublet APO Refractors

For the Tele Vue-60, -76, and -85mm scopes, we met our goal to achieve apochromatic performance in as compact a package as possible. Since we could achieve the desired optical performance using a doublet design, including two more air-to-glass surfaces to create a triplet would have added additional weight in the wrong place, plus assembly and material costs with little performance benefit to the end-user. As you’ll notice from the specifications, as the aperture decreases the speed of each scope increases. The smaller aperture allows shorter focal length designs while retaining very similar optical performance between the three models.

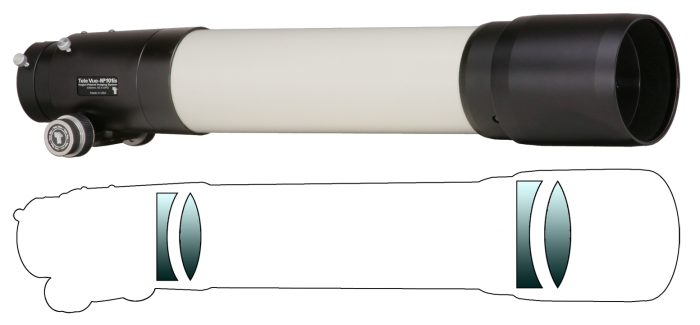

Tele Vue Large Nagler-Petzval APO Refractors

Al Nagler took Petzval’s portrait lens concept, using widely spaced doublets, and patented a fast telescope design version for the purpose of testing eyepieces. The 5”, f/4 MPT (Multi-Purpose Telescope) with its fast speed, wide, and flat field, led to a series of continuous improvements, primarily in color correction. By 2001, the NP101 (Nagler-Petzval) scope was the ultimate culmination of 20-years of refinement toward optical perfection for the “multi-purpose” concept. A review in the Backyard Astronomer’s Guide said: “optics don’t get any better than this.” With Tele Vue Imaging System (“is”) telescopes, we have refined our instruments and optional equipment to match the capability of these large, small pixel CCD chips.

No triplet design

regardless of

configuration can

meet all these criteria.

The 4-element objective designs of the NP101is and NP127is consist of two widely spaced, air-spaced doublets. It is a misnomer to think of these designs as a “doublet objective with a built in field flattener” as the rear group of the objective is in considerable power-space and corrects the un-corrected aberrations of the front group. This configuration, along with the chosen glasses, was necessary to achieve the desired aberration control at the exceedingly fast f/5.4 and f/5.2 focal ratios. Why so fast? In order to obtain as wide a true field both visually and for imaging, we chose as short a focal length as possible for which we could meet the desired correction of axial and lateral color, spherochromatism, astigmatism, coma, and field flatness. No triplet design regardless of configuration can meet all these criteria.

Nagler-Petzval “is” Scope Building

In addition to the same type of work that goes into building our smaller scopes, the more complex “is” scopes require additional build and inspections procedures. Due to the potential load of imaging equipment, the focusers are subjected to a “sag” test in which the deflection of the drawtube is measured in thousandths of an inch along the travel and in four rotational positions using a 10-pound weight. The mechanical assembly is then laser aligned. Once the optics are in place and the scope is collimated, it is put on a proprietary collimating rig that allows us to inspect the edge-field performance to ensure the tilt-adjustable end ring is parallel to the image plane.

Weighted Sag Measurement, Mechanical Laser Alignment, & Field Inspection

The “secret” to our scopes is that we start with a clear understanding of what we want to achieve and then create the best possible design to achieve our goals. There is little reason to “mess with success” after that unless we can make a meaningful and cost-effective improvement.

Tele Vue Service

On a final note, Tele Vue offers a range of telescope repair, refurbishment, and upgrade services should your scope ever need anything. (See Tele Vue Scope Renaissance! for an example.)

- TV-60 page on our website (mobile version)

- TV-76 page on our website (mobile version)

- TV-85 page on our website (mobile version)

- TV-NP101is page on our website (mobile version)

- TV-NP127is page on our website (mobile version)

- TV-NP127fli page on our website (mobile version)

- Tele Vue Telescope Recommendations and Specs (PDF)

- All Tele Vue telescopes come with a 5-year Limited Warranty

Did you observe, sketch, or image with Tele Vue gear? We’ll like your social media post on that if you tag it #televue and the gear used. Example:

televue #tv85 #ethos #jupiter

Do you want your Tele Vue images re-posted on Tele Vue Optics’ Social Media accounts? Use this hashtag for consideration:

#RPTVO